I. Verification

4. Solution of numerical benchmark for

thermal and viscous flows [7]

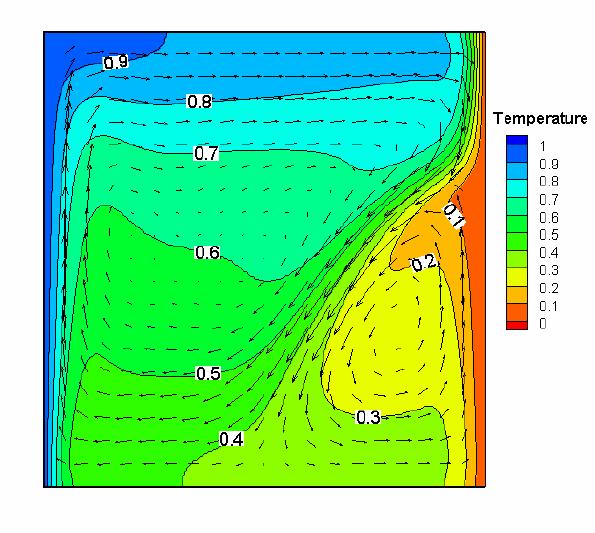

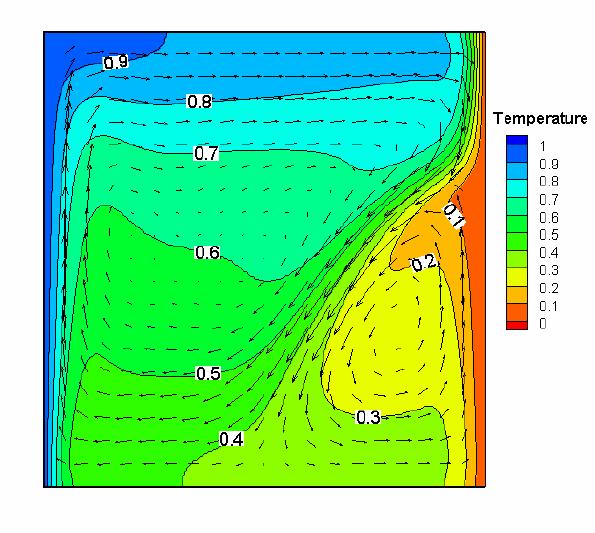

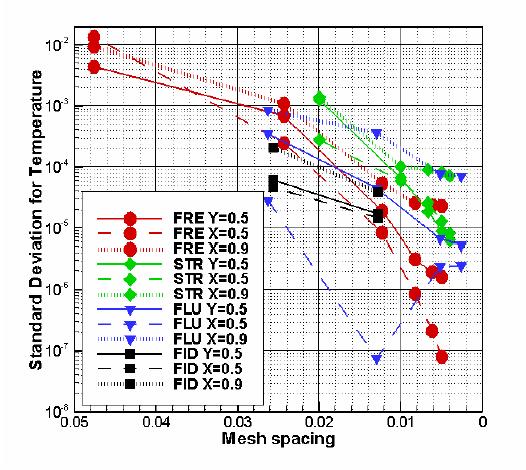

- Figure 1 shows the velocity

and temperature fields of obtained solution for defined problem. Two main circulations are clearly

visible: an

upper clockwise circulation transporting hot liquid towards the top

wall and

back along the isotherm of the density extremum, and a lower

counter-clockwise

circulation within the cold wall region. At the cold wall, the

descending hot

liquid interacts with the rising cold liquid. This creates a distinct

saddle

point in vicinity of the wall, approximately at about two-thirds of the

cavity

height. Position of the saddle point, given by the balance of competing

positive and negative buoyancy forces, appears to be very sensitive to

inaccuracies of the numerical solutions.

Figure

1.

Natural convection of water.

Temperature and velocity field for the fine mesh solution of FRECON3V

(run

FRE6)

- In order to compare performance of

different codes in terms of their ability to reproduce fine details of

the flow

structure it is not sufficient to verify agreement of global flow field

parameters,

like those given in Tables 2-6. It appears that small deviation in

their value

(2% - 5%) from the reference solution, usually reported as reasonable

or

even excellent agreement, corresponds to distinct changes of

the flow

pattern. Such changes become responsible for differences in the local

mass and

heat transfer in the system. These effects can be perhaps neglected if

only

insulation or heat drainage are of the main interest. But they are not

tolerable when phase change processes are present (e.g. freezing of

water) or

transport of small inclusions is an important issue.

- Hence, to obtain

better insight into differences or similarities of the flow structures

obtained

from the investigated solvers, the second step of the verification

procedure is

proposed. It is based on calculating deviation of the velocity profiles

extracted along three selected lines: horizontal centreline y=0.5,

vertical

centreline x=0.5 and vertical line passing through the mixing zone and

the

stagnation point at the cold wall (x=0.9). Locations of the lines are

selected

in such way that for any investigated mesh resolution they still match

the

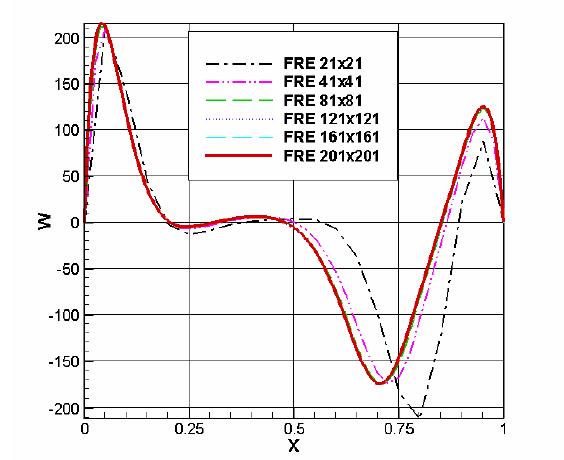

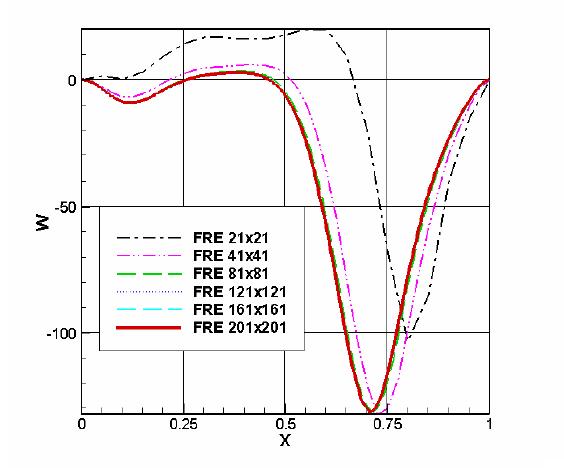

nodes location, and additional interpolation errors are avoided. Figure

3 shows

example of the velocity profiles along the horizontal and vertical

symmetry

lines of the cavity for meshes from Table 2. It is worth noting that

the errors

of the simulation performed for the quite fine mesh (FRE2) may reach

almost 50%

for the vertical velocity (Fig. 3a). Also large errors are present for

the

horizontal velocity component obtained for the coarse mesh (Fig. 3b).

This test

indicates that modelling of a simple natural convection in the presence

of the

strongly non-linear variation of water density requires careful

analysis of

results and very fine meshes.

-

Figure3. Velocity profiles extracted

for

the horizontal centre-line Y=0.5

(a)

– vertical velocity

component

(b)

- horizontal velocity component

- The mesh sensitivity analysis

performed for five investigated codes gives us some reference about

convergence

rate and allows to estimate their asymptotic behaviour. For more

detailed

comparison the flow field obtained using FRECON3V for

the fine mesh (201x201) was selected. The

velocity and temperature profiles extracted along above mentioned lines

are

approximated with the high order polynomial and treated as a reference

(benchmark) solution. The numerical values of the polynomials

coefficients are

given in Appendix. The fifteen digit accurate values of the

coefficients are

given to ease comparisons in the future. Obviously, it will be easier

to quantify

accuracy using well defined analytical functions than by overlapping

reproduced

figures.

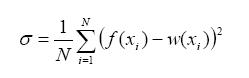

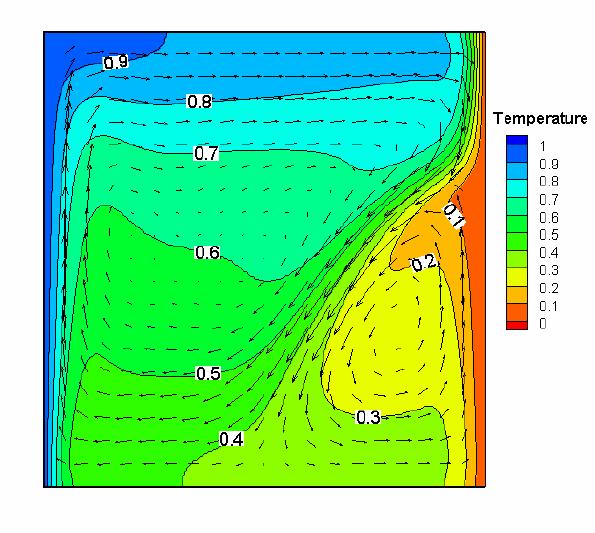

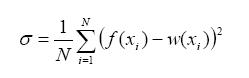

- An assessment on the accuracy of the

solution

is obtained calculating relative differences in terms of defined below

standard

deviations s, evaluated for

the polynomials

describing benchmark profiles and corresponding values extracted from

the

interrogated solution:

(4.1)

- Here, N gives number of discrete

points (corresponding to the discretization nodes) of the interrogates

solution, w(xi) polynomial value of the benchmark solution

for the

point xi , and f(xi) value of the analyzed

discrete

solution for the point xi.

- Nine indicators are defined according

to the

above definition and used to evaluate accuracy of the solutions: σu1,

σw1, σt1, σu2,

σw2, σt2, σu3,

σw3 and σt3. They describe standard deviations calculated

for two velocity components U ,W and temperature T for

profiles

extracted at centrelines Y=0.5, X=0.5,

and vertical line X=0.9.

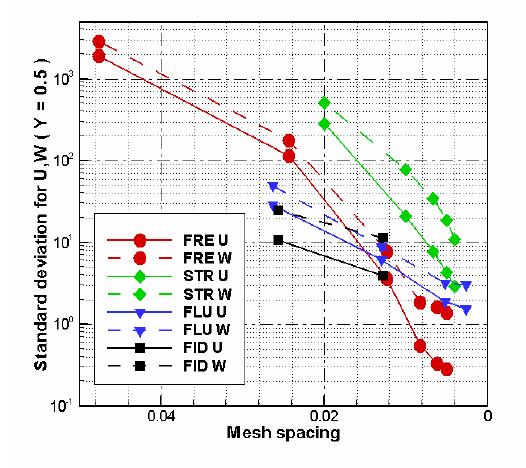

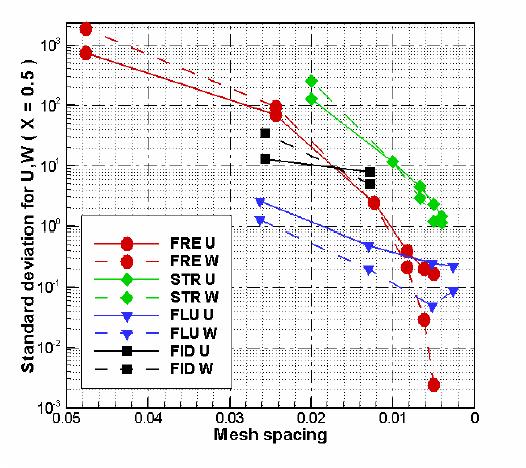

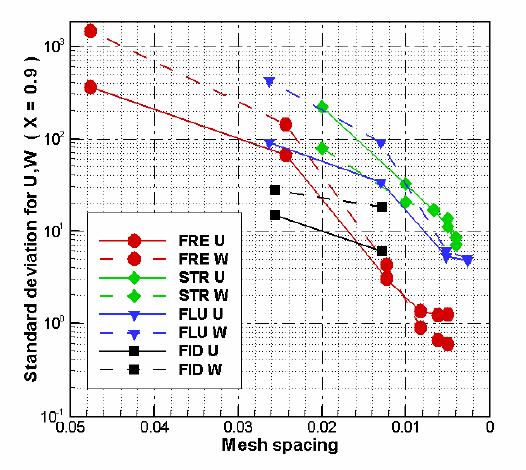

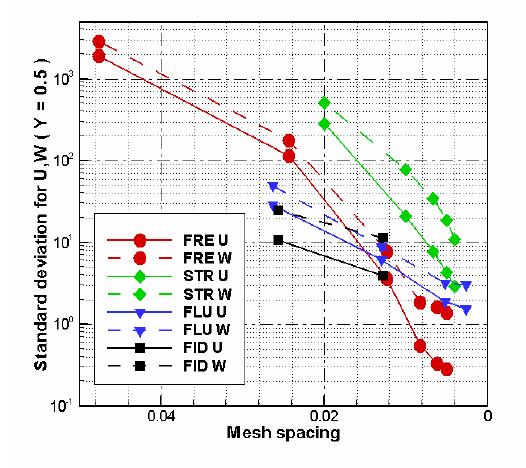

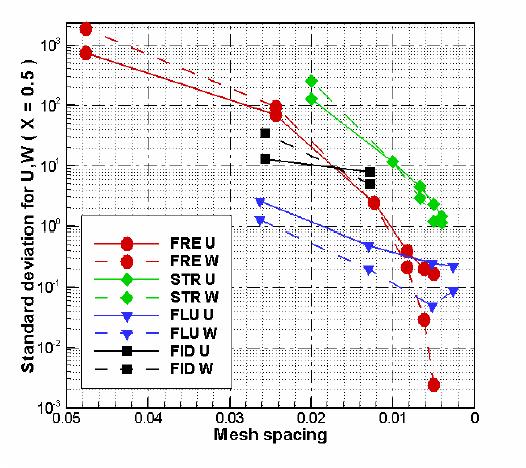

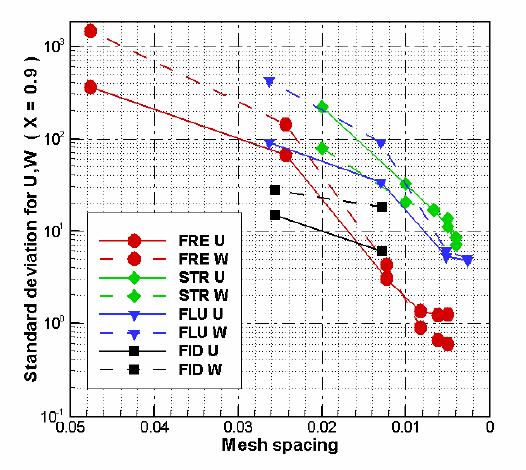

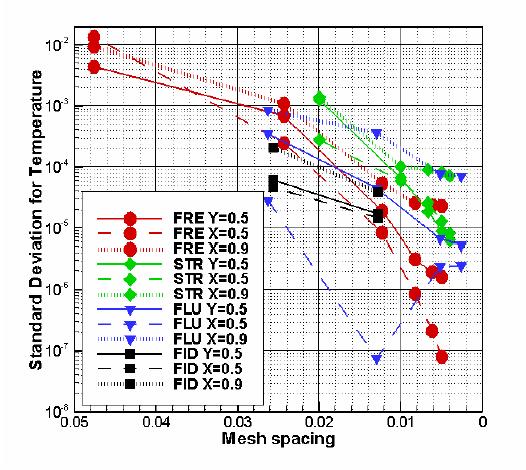

- The proposed accuracy indicators can

be easily used to assess performance of any numerical solutions,

regardless of

dimension of the mesh size, as well as to estimate the rate of

convergence of

successive solutions. Data collected in Table 7 are presented in Figure 4. The figures show, respectively,

mesh dependence of σ u1 , σ w1 for

velocity profiles at

Y=0.5, σ u2 , σ w2 for

velocity profiles at X=0.5, σ u3, σ w3 for

velocity

profiles at X=0.9, and σt1 , σt2, σ t3 for

three temperature profiles at Y=0.5, X=05

and X=0.9.

- The

value of σ u1 , σ

w1 , σ u2

σ w2 ,

σ u3, σ w3 , σ

t1 ,σ t2 ,σ t3 for the fine

mesh FRECON solution

(FRE6) was taken as a reference error indicator. Generously setting

cut-off

value for standard deviation equal 3 we come to conclusion that only

solutions

FRE4-7 and FLU3 are close enough to the reference solution to be

assumed as the

correct ones.

- From Figure 4 it is easily visible

that the

rate of convergence of SOLVSTR is much slower in comparison with

FRECON. From

the other hand, analysing the values of the

indicators on successive meshes we may find that the rate of

convergence for FLUENT, FIDAP is almost linear in contrast to the much

faster

convergence of FRECON or even SOLVSTR. It is rather surprising as the

both

commercial codes claim to use second order approximations.

- The stream function - vorticity

solver SOLVSTR

needs almost triple mesh refining (250x250) to reach accuracy

comparable with

that of other “mesh related” codes. One of the possible

explanations of such

behaviour is the lack of “upwind” schemes in SOLVSTR code.

Moreover,

improvement of the ADI algorithm and replacement of Gauss-Seidel

algorithm by

relaxation methods like SOR, CG, GMRES, could lead to better

performance of the

code.

- It is

worth noting that convergence of temperature is relatively easy to

reach, and

even for the most coarse meshes temperature profiles are practically

“exact”.

It indicates robustness of the energy equations and relatively small

effect of

the convective term on the resulting temperature distribution. It is

rather

surprising result, and it suggest that use of temperature as a

convergence

indicator can be dangerously misleading. At least for the analysed flow

configuration.

- A mesh-free code SOLVMEF using diffuse approximation

fails this very

sensitive test of accuracy. On the other hand the extremely long time

of

calculation does not allow for mesh refinement to increase the

accuracy. Global

and average indicators show proper trend of convergence. However, the

main

disadvantage of this method, its slow rate of convergence, is still

challenging

for future research.

Figure 4. Mesh dependence:

(a)

– standard deviations σ u1 , σ w1 for

velocity profiles

at Y=0.5;

(b)

- standard deviations σ u2 , σ w2 for velocity profiles at X=0.5,

(c)

-

standard deviations σ u3, σ w3 for

velocity profiles at

X=0.9;

(d)

- standard deviations σt1 , σt2, σ t3 for

three temperature profiles at Y=0.5, X=0.5

and X=0.9.