II. Validation

2. Definition of experimental benchmark

2.1. Experimental

set-up

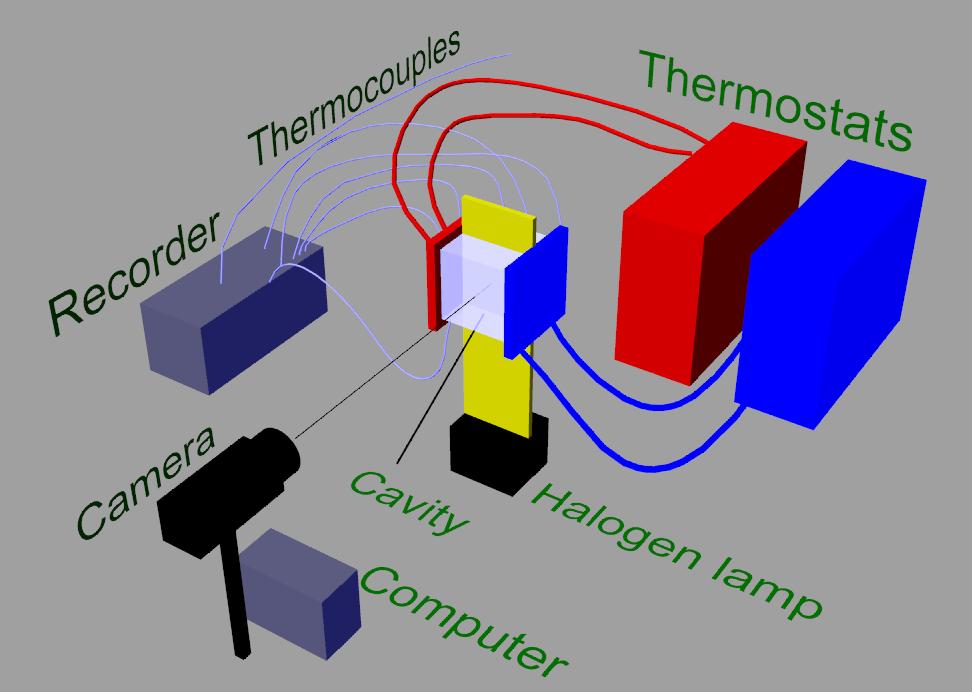

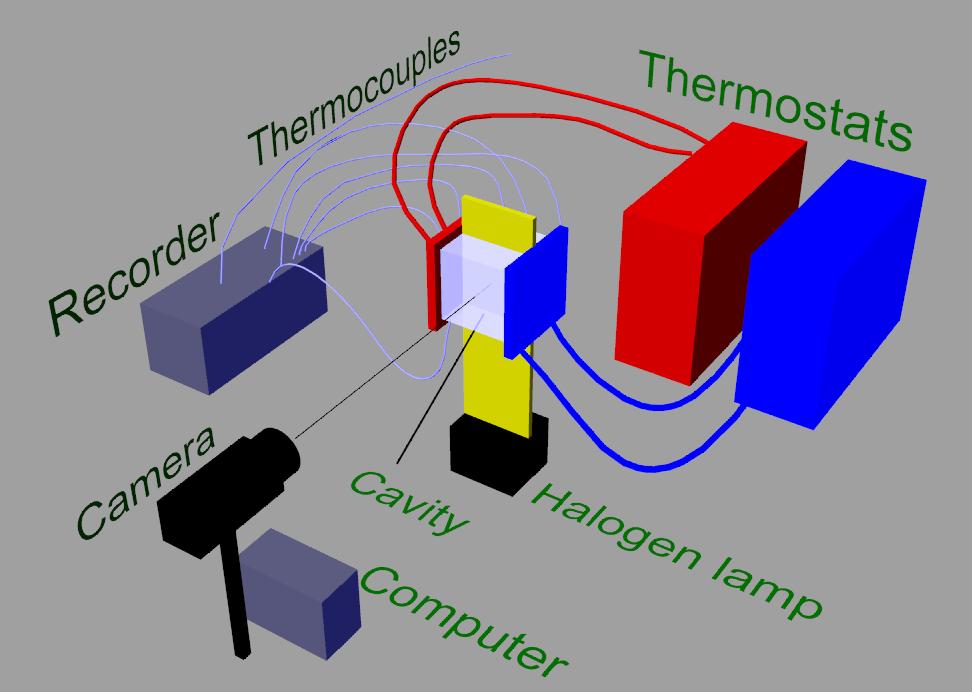

Figure 5 shows experimental set-up used in validation studies.

Figure 5 Sketch of experimetal set-up

Experimental set-up conists of :

- 3CCD colour camera XC003/P (Sony) with 32 bit module for image aquisition (Imaging Tech) (max. resolution 768x542 pixels)

- CMOS PCO 1200 hs black and white high speed camera (PCO Imaging)

with internal frame graber for image aquisition (max. resolution

1280x1024 pixels, maximum frame rate: 40720 fps)

- cavity

- halogen lamp (1000 Watt)

- two thermostats

- multi channel precision thermometer (PTM 3040 Prema Semicondutor GmbH)

- two PC computers

- set of thermocouples NiCr - NiAl of type K or Pt-100

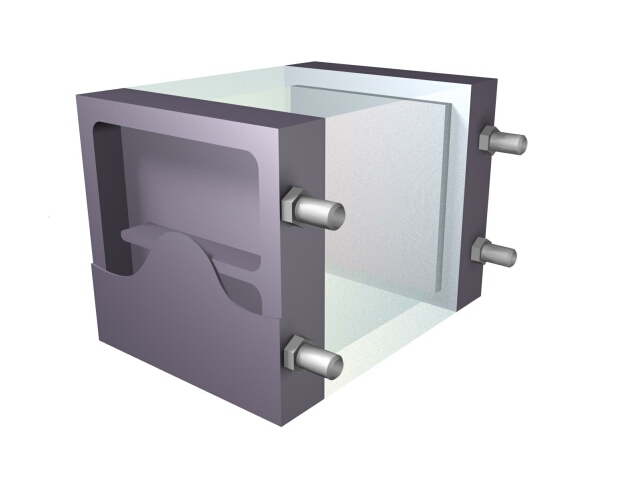

Figure 6 shows a cavity used in experiments. All dimenisons of the

cavity can be taken from files in Auto Cad format (*.dwg), which

present corss-sections of the cavity

files in *.dwg format : Central Vertical Cross-Section, Central Horizontal Cross-Section

files in *.jpeg format : Central Vertical Cross-Section, Central Horizontal Cross-Section

Figure 6 Sketch of the cavity

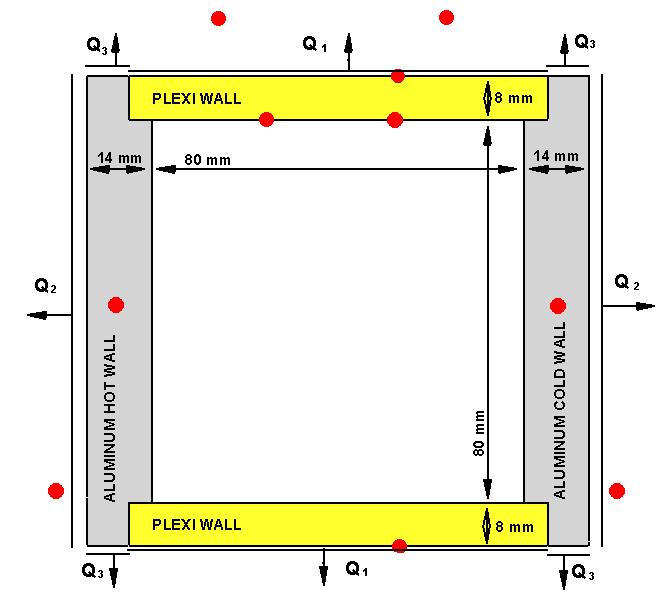

Figure 7 Central cross-section of the cavity with location of thermocoupes

2.2. Experimental

techniques

We made use of following experimental techniques:

Particle Image Velocimetry

Particle Image Velocimetry was used to obtain 2D velocity field for the

central cross-section of the cavity (Figure7). This method allows for

non-destructive and quantitative measurementd of velocity fields. The

first stage of the measurements include recoridng sequences of

images. Tracers are suspended uniformly inside the cavity. Two kind of

tracers were used in our measurements: thermocromic liquid crystals(see

details in next chapter) and pollens (Pinus silvestris, Pinus

nigra).

In the next stage, two subseqent flow images are analyzed with the use

of digital image techniques in order to obtain relative displacement of

tracers. Images ared divided into windows (sections) and for these

windows displacement is calculted on the basis of analysis of

correlation coeficients, FFT or others [XX,XX,XX].

Taking into account calculated relative displacement and time delay

between images velocity field is obtained for this pair of images. By

repeating this procedure for each of two subsequent digital images from

the recorded sequence, we were able to obtain series of velocity

fields. Then the average velocity field is calculated:

(X.X1)

Standard deviation for the whole velocity field is also analyzed in

order to determine the most appriopraite time delay between images:

(X.X2)

Precsision of average velocity fields was evaluted on the basis of mean dispersion of the average (X.X1), defined as follows:

(X.X3)

Triple maximum value of the mean disperison (X.X3) in the

whole velocity field was used as the quantitative measure of precision

for all velocity measurements making use of PIV.

Particle Image Thermometry

Particle Image Thermometry was used to obtain 2D temperature field for

the

central cross-section of the cavity (Figure7). This method allows for

non-destructive and quantitative measurementd of temperature fields.

The

first stage of the measurements include recoridng sequences of

colour images. As tracers the Thermochromic Liquid Crystals were

used, which were suspended uniformly inside the cavity. These tracers

reflect white halogen light only in the central cross-section of the

cavity (see Figure 5). Thermochromic liquid crystals change their

colour with temperature.

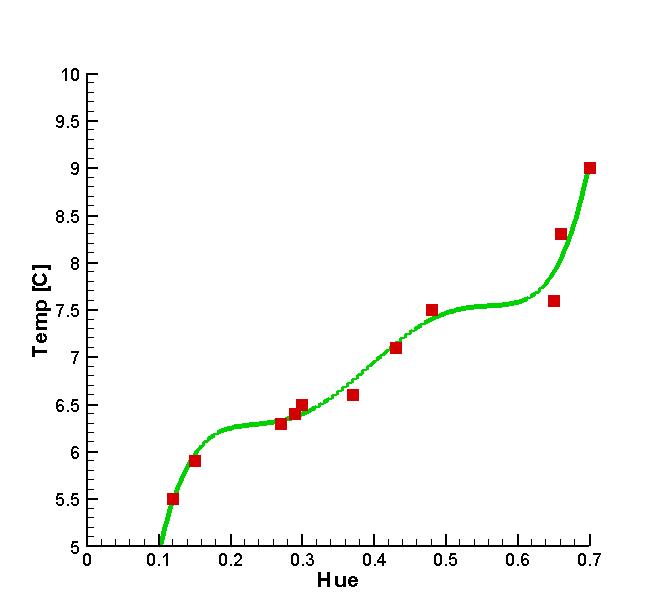

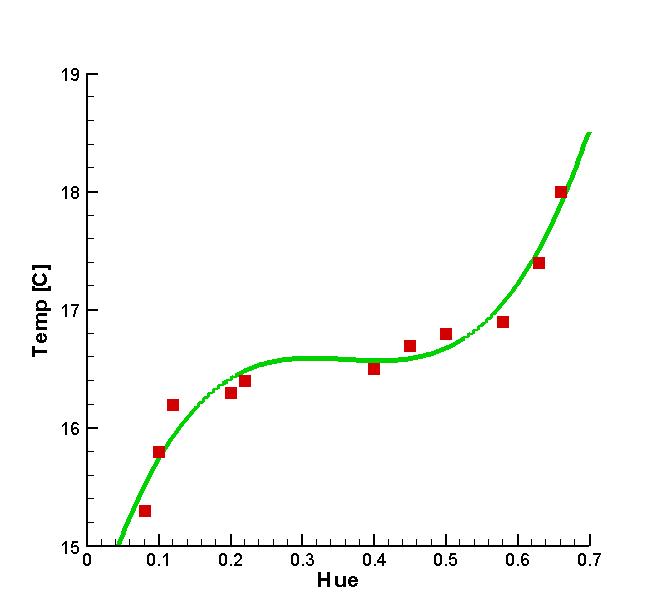

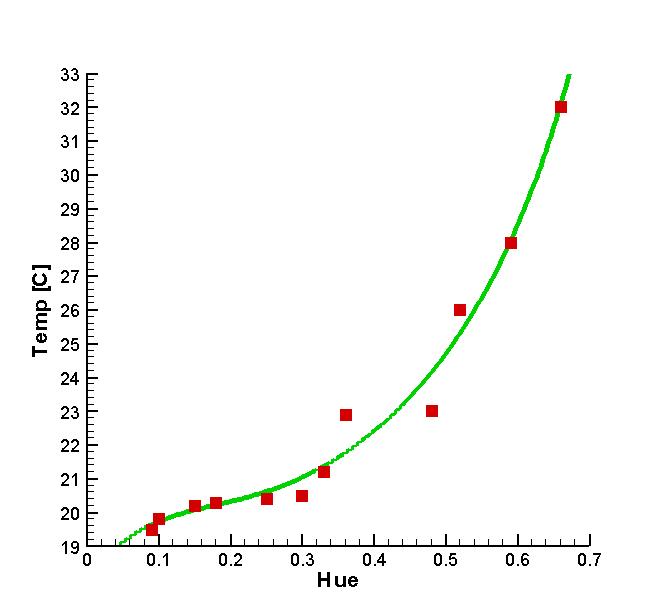

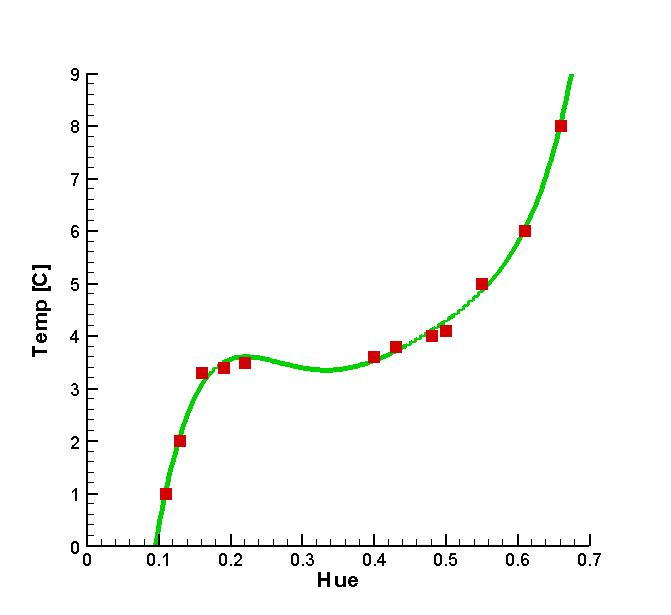

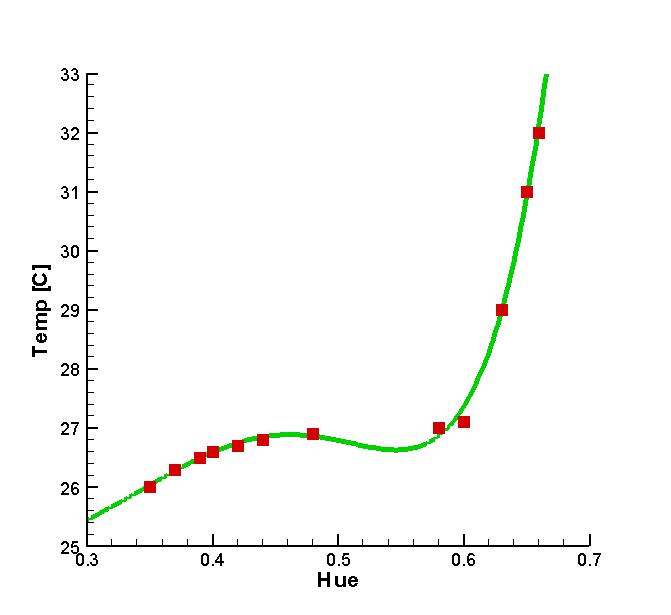

Colour images are analyzed making use of digital image

procedures. Temperature fields are obtained on the basis of

digital coulor images making use of calibration curves. Calibration

curve binds one of the component of digital image (H - Hue) with local

temperature. Form of this curve is determined in calibration process

for each of the Thermochromic Liquid Crystal applied.

Table 2.2.1. Thermochromic liquid crystals used in our researach

|

|

Symbol

|

Vendor

|

Initial temperature of sensitivity

|

Range of colour-play

|

|

1

|

BM100/R6C12W/S33

|

Hallcrest Ltd.

|

6 °C

|

12°C

|

|

2

|

TM445 (R17C6W)

|

BDH

|

17°C

|

6°C

|

|

3

|

TM317 (21C)

|

BDH

|

21°C

|

20°C

|

|

4

|

MixC (TM912+)

|

Merc

|

-2°C

|

10°C

|

|

5

|

TCC 1001

|

Merc

|

27°C

|

4°C

|

Calibration process was performed for each of TLCs from Table 2.2.1.

Calibration curves are presented below with analitical formula in form

of polynom.

Fiugre 8. Hallcrest

Figure 9. TM445

Figure 10 TM312

Figure 11 Mix C

Figure 12 TC1001

Point temperature measurements

High Speed Imaging - 2D Visualisation

2.3. Sensitivity

analysis