Dynamics of melt spinning

processes accounting for the effects of flow-induced crystallizations has been

studied by mathematical modeling and computers simulations of high-speed melt

spinning [1-3] and pneumatic processes [4-8]. Axial profiles of melt spinning

processes (polymer velocity, temperature, tensile stress and crystallinity as dependent on the process and material

parameters are determined. Effects of crystallization on the dynamics of melt

spinning and rheological behavior is discussed [1]. Effects of on-line zone

heating during melt spinning of PET fibres was

studied [2]. Crystallinity-dependent polymer viscosity results in

limited take-up velocity and filament thickness and bifurcation leading to

three regions of the processing conditions leading to amorphous, partly

crystalline and inaccessible ranges [3].

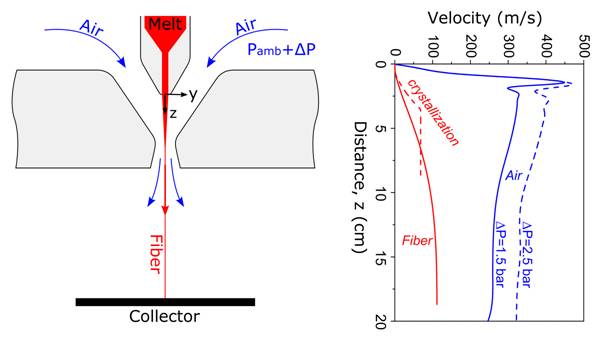

A model for stationary melt blowing of

nonwovens [4-6] and pneumatic melt spinning by ultrasonic air jet in the Laval

nozzle [7,8] is proposed and applied for iPP and PLA

with the effects of on-line stress-induced crystallization on the polymer

viscosity and rheological relaxation time. The role of the viscous friction heat in the polymer bulk has

been discussed for fast air-drawing of the polymer melt. Axial profiles of the

polymer velocity, temperature elongation rate, filament diameter, tensile

stress, and extra-pressure were computed for the pneumatic processes of

non-woven formation. The effects of the air-jet velocity, die-to-collector

distance and polymer molecular weight are discussed.

The model allows to discuss non-linear stress-optical relationship reflecting

online molecular orientation, as well as online crystallization of the polymer

filament if it occurs. Significant online

extra-pressure in the filament was predicted in the case of supersonic air jets

as resulting from polymer viscoelasticity, which

could lead to longitudinal splitting into sub-filaments [5-7].

The filament velocity at the collector increases

significantly with increasing air compression, from the values typical for

high-speed melt spinning up to values by two folds higher. The increase in

filament velocity is limited by the effects of online oriented crystallization

at higher air compressions. Influence of the inlet air compression, melt

extrusion temperature and weight-average molecular weight on the axial profiles

of the melt spinning functions is discussed, as well as on the development of

amorphous orientation and online oriented crystallization.

Cross-sections of the longitudinal die

assembly with the

[1]. Ziabicki A., Jarecki

L., Sorrentino A., The role of flow-induced crystallization in melt spinning, E-POLYMERS, no. 072, 2004.

[2]. Blim A., Jarecki

L., Effects of zone heating on PET fibers

structures and dynamics of melt spinning process.

Part II. Mathematical model),

POLIMERY, 52, 686-700, 2007.

[3]. Ziabicki A., Jarecki

L., Crystallization-controlled

limitations of melt spinning, JOURNAL OF APPLIED POLYMER SCIENCE, 105,

215-223, 2007.

[4]. Jarecki L., Ziabicki

A., Mathematical modeling of the

pneumatic melt spinning of isotactic polypropylene Part II. Dynamic model of melt blowing, FIBRES AND TEXTILES IN EASTERN EUROPE, 16,

17-24, 2008.

[5]. Jarecki L., Ziabicki A., Lewandowski Z., Dynamics

of air drawing in the melt blowing of nonwovens from isotactic polypropylene by computer

modeling, JOURNAL OF APPLIED POLYMER SCIENCE, 119, 53-65, 2011.

[6]. Jarecki L., Błoński S., Zachara A., Blim A., Computer

modeling of pneumatic formation of superthin fibres, COMPUTER METHODS IN MATERIALS SCIENCE /

INFORMATYKA W TECHNOLOGII MATERIAŁÓW, 11, 74-80, 2011.

[7]. Jarecki

L., Błoński S., Blim A., Zachara A., Modeling

of pneumatic melt spinning processes, JOURNAL OF APPLIED POLYMER SCIENCE, 125, 4402-4415, 2012.

[8]. Jarecki L., Błoński S., Zachara A., Modeling of

Pneumatic Melt Drawing of Poly-L-lactide

Fibers in the