Understanding of the kinetic mechanisms

governing development of lamellar thickness distribution is under the scope

of publications [1,2] and

creation/disappearance of polymorphic phases during crystallization is the

subject of papers [3-7].

An unique mathematical model of development of

thickness distribution of lamellar crystals during crystallization from the

polymer melt has been proposed [1]. The model can be used to predict or design

the thickness distribution of crystals by adjusting thermal conditions and crystallization time, without the need of synchrotron

measurements. Continuity equation for

the lamellar thickness distribution is proposed and solved. The model accounts

for fast creation of doubled crystals during a “doubling time” and slow

logarithmic thickening subsequent to the doubling transformation. The approach

concerns crystallization in systems without mesophase

involved in the transformation. It was also shown that the thicknesses range of

plate-like crystals created during crystallization is limited depending upon

crystallization temperature [2].

Development of lamellar thickness

distribution at consecutive conversion times (indicated) computed for isothermal

crystallization of PE at 123oC[1].

A map of nucleation behaviour for plate-like

crystallization [2].

Fundamentals of a kinetic

model of multiphase polymorphic crystallization proposed by professor Andrzej Ziabicki [3] has been

developed [4-6] and applied [7]. Using the model, three-phase system composed

of an amorphous component and two polymorphic solid phases has been considered.

The approach predicts development of the phase composition under different

thermal conditions. It was shown, how the modification of material

characteristics affect on polymorphic crystallization kinetics [5] and how

proportions between polymorphic phases can be regulated by the change of

concentration of predetermined nuclei and temperature [6]. Limited degree of

crystallization which results from molecular constrains in polymer systems is

introduced in the model.

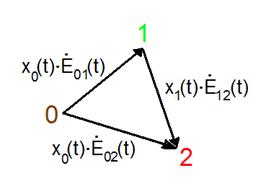

|

|

|

Phase

transitions and development of the phase composition in a three-phase system [4].

[1]. Jarecki L., Misztal-Faraj B., Kinetic

model of polymer crystallization with the lamellar thickness distribution, EUROPEAN

POLYMER JOURNAL, 73, 175-190, 2015.

[2]. Misztal-Faraj B., A simple

model of plate-like crystallization with constant plate thickness, JOURNAL OF

MATERIALS RESEARCH, 28, 1224-1238,

2013.

[3]. Ziabicki

A., Nucleation-controlled multiphase

transitions, JOURNAL OF CHEMICAL PHYSICS, 123, 174103-1-174103-11, 2005.

[4]. Ziabicki A., Misztal-Faraj B., Modeling of

phase transitions in three-phase polymorphic systems: Part I. Basic

equations and example simulation, JOURNAL

OF MATERIALS RESEARCH, 26, 1585-1595, 2011.

[5]. Misztal-Faraj B., Ziabicki A., Modeling

of phase transitions in three-phase polymorphic systems: Part II.

Effects of material characteristics on transition rates, JOURNAL OF MATERIALS RESEARCH, 26, 1596-1604, 2011.

[6]. Misztal-Faraj B., Ziabicki A., Effects

of predetermined nuclei and limited transformation on polymorphic crystallization in a model polymer, JOURNAL OF APPLIED POLYMER SCIENCE,

125, 4243-4251, 2012.

[7]. Sajkiewicz P., Gradys A., Ziabicki A., Misztal-Faraj B., On

the metastability of beta phase in isotactic polypropylene: Experiments and numerical simulation, E-POLYMERS, No.124, 1-20, 2010.